Essential Guide to Effective Workbench Building: Get Started in 2025

Building a workbench can be a rewarding project, providing you with a stable and organized space for all your woodworking and DIY tasks. In this comprehensive guide, we will cover everything from how to build a workbench to design ideas and storage solutions, ensuring you are well-prepared to create your perfect workspace in 2025.

Understanding Workbench Plans

Before diving into your workbench construction, it’s essential to have a clear plan. DIY workbench plans serve as the foundation for successful woodworking bench construction. Start by determining the available space in your workshop, and then select the dimensions that best fit your needs. Common workbench dimensions vary, but a height of around 34-36 inches is comfortable for most users. Tailoring your plans to accommodate these dimensions will enhance ergonomics and usability.

Types of DIY Workbench Plans

When selecting plans, consider the type of workbench you’ll be constructing. Popular options include:

- Folding workbench features for those with limited space.

- Mobile workbench designs with wheels for easy portability.

- Heavy-duty workbench kits for more extensive woodworking projects.

Choosing the right plan can greatly influence the success and functionality of your workbench. Be sure to incorporate your unique needs and preferences in your choice.

Workbench Dimensions and Layout

To maximize workbench functionality, carefully consider the layout of your workspace. The traditional recommendation for workbench height should align with your elbow height to maintain comfort during work. Additionally, think about necessary workbench storage solutions such as built-in drawers or shelving units to keep tools and materials organized. If working on various projects, a versatile workbench workspace layout will help you transition smoothly between different tasks.

Choosing the Right Materials for Your Workbench

Selecting the best materials is crucial when building a workbench. The choices you make will influence durability, appearance, and functionality. Suitable materials can include hardwood, plywood, or laminate, with each offering distinct advantages. For instance, laminated workbench tops provide increased durability and a smooth surface for easy maintenance. Mind that using the right essential tools for workbench during construction will further ensure the quality of your final product.

Best Workbench Materials

Best workbench materials can vary based on your specific needs:

- Wood Species for Workbench: Hardwoods such as maple or birch offer excellent strength and longevity.

- Metal Frame Workbench Options: For added strength, consider using steel framing combined with wood tops.

- Plywood Workbench Construction: A budget-friendly option that can be adapted with different finishes.

Choosing the proper materials will ensure a stable workspace capable of withstanding the demands of heavy-duty projects.

Workbench Finishes and Maintenance

To keep your workbench looking good and performing well, apply suitable workbench finishes tips that protect against wear and tear. Traditional oil finishes tend to nourish the wood, while synthetic finishes can offer more substantial protective qualities. Moreover, regular maintenance such as cleaning the surfaces and checking for structural stability will ensure a long-lasting and sturdy workbench.

Design Ideas for Your Workbench

Getting creative with your workbench design ideas can transform a standard utility bench into a personalized workspace. Incorporating innovative features and adapting to your specific projects can enhance both efficiency and enjoyment while working.

Ergonomic Workbench Setup

When setting up your workbench, keep in mind the importance of ergonomics. An ergonomic workbench setup minimizes strain and promotes comfort. Ensure that your primary tools and materials are within easy reach to reduce unnecessary movements. Adjustable height options can accommodate various user preferences and tasks, allowing for a flexible workspace that adapts as your projects evolve.

Mobile and Adjustable Workbench Solutions

For those who require a versatile workspace, mobile workbench solutions should be considered. These can be customized with wheels for easy mobility, allowing you to transform your garage into a workshop whenever needed. Furthermore, adjustable height workbench systems can key into maximizing productivity and flexibility, catering to various tasks while commending user comfort.

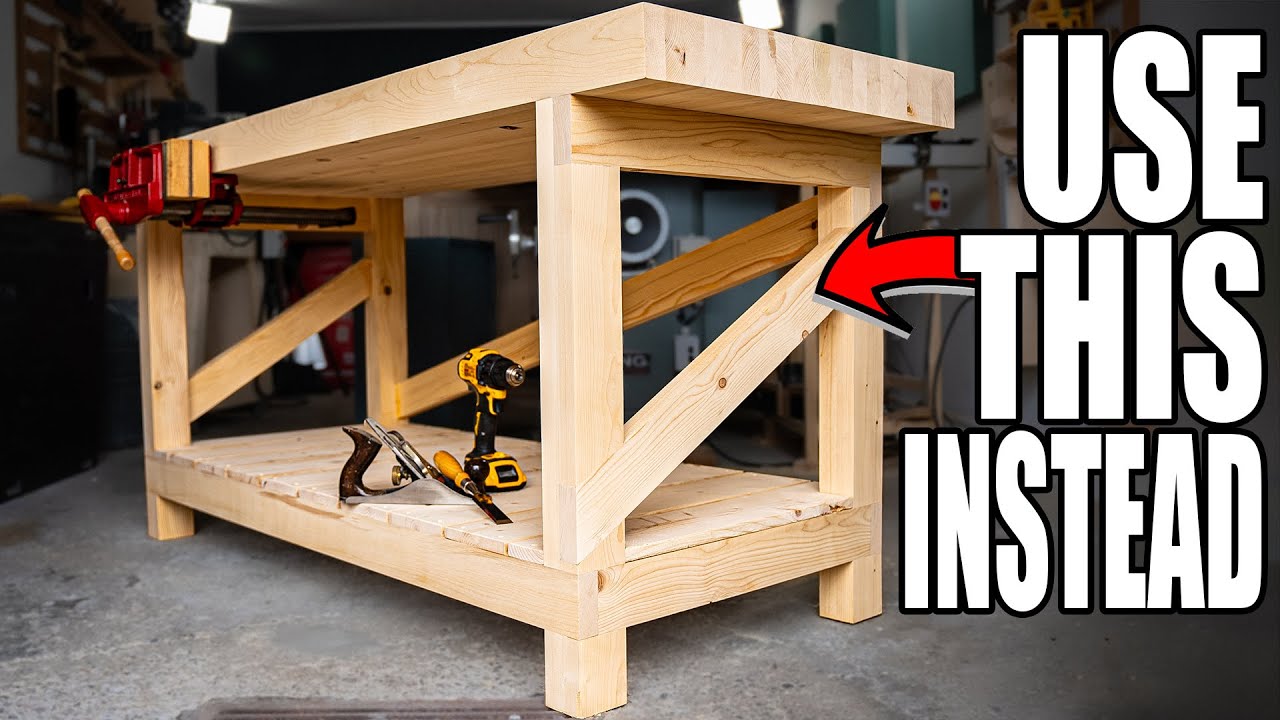

Building a Workbench from Scratch

If you’re a DIY enthusiast, you might prefer building a workbench from scratch. This route allows you to customize your workbench based on personal needs, preferences, and specific tasks. Start by drafting a detailed plan drawing on your earlier research on dimensions and materials to ensure a purpose-built workspace.

Workbench Assembly Guide

To guide you through the assembly, follow these steps:

- Gather all materials and tools, such as a saw, drill, level, and screws.

- Assemble the frame, ensuring it’s square before tightening all connections.

- Attach the top surface, ensuring it’s secured and stable.

- Implement any additional features, such as clamps or vices.

This step-by-step workbench assembly guide can streamline the process and help avoid common pitfalls.

Test and Customize Your Workbench

Once constructed, thoroughly test your workbench for stability and functionality. Make necessary adjustments based on your experience while working. This is a great time to include features like built-in drawers for tool organization or add an integrated method for dust collection for cleaner workspace habits.

Key Takeaways

- Plan accordingly for dimensions and layout to enhance functionality.

- Choosing the right materials is essential for durability and effectiveness.

- Consider ergonomics in your design to improve comfort and efficiency.

- Build custom features to suit your specific use cases.

FAQ

1. What are the basic tools needed for workbench construction?

Essential tools for constructing your workbench typically include a circular saw, drill, measuring tape, clamps, and a level. Acquiring these tools before starting will help ensure a smooth construction process. Depending on your chosen materials, you might also need a sander or table saw to achieve the precision required for your projects.

2. How do I maintain my workbench?

Regular workbench maintenance tips you should follow include cleaning the surface after use, checking for stability, lubricating moving parts, and treating surfaces with appropriate finish options to prolong their life. Keeping your workbench organized will also contribute to its overall maintenance and functionality.

3. What are some good workbench plans for beginners?

For beginners, workbench projects for beginners can focus on simple designs requiring fewer materials and tools. Look for projects emphasizing stability and ease of assembly, such as a basic plywood workbench or a wall-mounted foldable option for those with limited space.

4. What kind of finish should I use on my workbench?

Choosing a workbench finish depends on your materials. Ongoing oil finishes are useful for wood surfaces, while harder surfaces might benefit from polyurethane or lacquer. Ensure any applied finish is safe and durable for your intended uses, allowing for straightforward cleanup and less wear over time.

5. Are there portable options for a workbench?

Yes, numerous portable workbench solutions exist that allow easy transportation and setup. Look for models with folding features or built-in wheels, ideally designed for lightweight transport while still offering stability during use. These can be particularly beneficial for those needing a workspace in various locations.

6. How do I optimize my workbench space?

To optimize workbench space, consider implementing vertical storage solutions and keeping essential tools within reach. Implement pegboards for tool organization and add shelves or drawers for smaller items to maintain a clutter-free workspace. These strategies enhance overall functionality and make your tasks more enjoyable.

With the right approach and understanding of woodworking principles, creating your dream workbench in 2025 is not only attainable but also an exciting project to undertake. Start planning today!