“`html

How Long Does It Take for Cement to Dry: A Comprehensive Guide for 2025

Understanding the how long does it take for cement to dry is crucial for any construction project. Properly managing the cement drying time ensures structural integrity, durability, and timely project completion. This guide will explore the drying process of cement, influential factors, and superior techniques to optimize drying time.

Cement Drying Fundamentals

The drying process of cement is essential for the successful hardening and durability of concrete structures. Knowing the basics can help manage expectations and ensure optimal performance. The stages of cement drying involve hydration and curing, where water interacts with the cement to form strong chemical bonds.

Understanding Cement Hydration

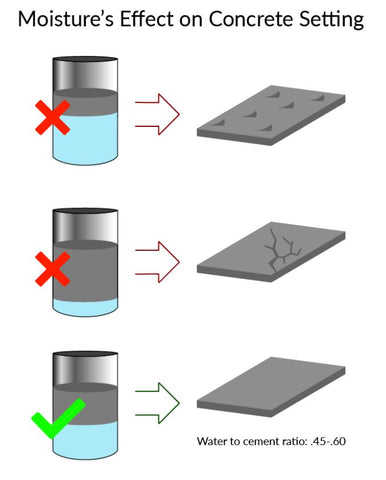

The hydration of cement begins immediately after mixing cement with water. Through a series of chemical reactions, the cement powder reacts, forming crystals that bind the aggregate. It is critical to accurately measure moisture content during this stage to avoid premature drying, which can lead to structural weaknesses.

Cement Setting vs. Drying Times

It’s vital to distinguish between cement setting time and cement drying time. While it typically takes about 24-48 hours for the cement to set firmly, the complete curing time for cement can extend to several weeks. While surface drying may occur, true curing involves continual moisture, often taking up to 28 days to achieve optimal strength.

The Role of Environmental Conditions

Environmental factors in cement drying play a substantial role in the outcome of any project. Temperature and humidity are two of the primary conditions that affect the cement drying duration. In warmer conditions, moisture can evaporate quickly, potentially leading to issues such as cracking or weakness in the cement. Conversely, moist and cold environments can hinder drying, necessitating adaptations, such as using quick-drying cement or utilizing cement curing compounds.

Factors Affecting Cement Drying Time

A successful cement installation depends on numerous factors that can influence cement drying time. Recognizing these elements can culminate in better project management and higher-quality results.

Mix Composition and Cement Type

The composition of the cement mix is critical. Different types of cement, such as rapid-setting cement or traditional cement, react differently to environmental conditions and can either speed up or slow down the cement mix drying time. Always choose a cement type best suited for your specific construction requirements.

Moisture and Temperature Control

Managing drying conditions is essential for consistent results. Moisture controls for cement drying involve ensuring adequate ventilation while maintaining a balanced humidity level. Cement drying in hot weather may necessitate additional curing measures to mitigate rapid evaporation, while cement drying in cold weather may require heating methods or insulated covers.

Implementing Effective Curing Techniques

Employing proper cement curing techniques can significantly improve hydration and strengthen the final product. Moist curing – involving frequent watering or wet coverings – keeps the surface hydrated, while other techniques like plastic sheeting can help trap moisture. These practices enhance the complete curing of cement.

Best Practices for Optimizing Cement Drying

To minimize drying challenges, understanding best practices for cement curing and drying can lead to more expeditious completion dates. Finding a balance in application techniques and considering accelerated curing for cement may present better outcomes.

Utilizing Modern Drying Methods

Modern methodology introduces the concept of accelerated curing for cement. This process employs heat, moisture control measures, or chemical accelerators to expedite strength gain, ensuring timely project completion without sacrificing quality. By warranting an environment conducive to optimal drying, construction projects will experience fewer delays.

Adhering to Established Standards

Adhering to established guidelines and standards in the industry ensures no steps are missed in the drying process. Familiarizing oneself with local building codes and resource availability can make the drying process smoother and free from unnecessary complications.

Monitoring Progress

Monitoring the progress during the cement hardening timeline assures that every stage adheres to optimal conditions. Using tools such as moisture measurement devices can help prevent damp areas that could hinder satisfactory results.

Key Takeaways

- Understanding the difference between setting time and curing time is essential.

- Environmental factors significantly influence drying times.

- Proper curing techniques enhance overall strength and durability.

- Adopting modern drying practices can lead to expedited timelines.

- Monitoring methods during the curing phase prevents long-term issues.

FAQ

1. How long does it take cement to be ready for foot traffic?

Typically, cement is ready for light foot traffic within 24-48 hours. However, the actual drying time is longer, requiring thorough hydration for desired strength.

2. What are the signs that cement has fully dried?

Signs of dry cement include a uniform texture, no visible moisture, and a solid, strong sound when tapped. However, complete curing can take weeks.

3. Can weather negatively impact the drying process of cement?

Absolutely. High temperatures and low humidity can cause rapid evaporation, while cold, damp conditions slow drying, potentially leading to curing issues.

4. Is there a difference between curing and drying cement?

Yes, drying refers to the removal of moisture, while curing preserves moisture for hydration to develop strength. Both processes must be managed for optimal results.

5. What determines the optimal drying time for cement?

The optimal drying time for cement is influenced by factors such as composition, environmental conditions, and curing techniques employed during the process.

“`