“`html

How to Effectively Calculate Error in Your 2025 Projects

Understanding Error in Measurements

Calculating error is a fundamental aspect of project management and scientific research. Understanding how to accurately measure error helps in assessing the reliability and accuracy of your data. Errors can be systematic, affecting the entire data set, or random, occurring unpredictably. Identifying the type of error is crucial, as it determines the method of calculation. For example, systematic error could stem from faulty equipment, while random error might arise from environmental fluctuations. Both types require distinct approaches for accurate error calculation in your 2025 projects.

Types of Errors

The two primary types of errors include systematic and random errors. Systematic errors often bias the results in a specific direction, which can be rectified by recalibrating equipment or applying corrective factors. In contrast, random errors are unpredictable and their effects vary; they result from uncontrolled variables that may affect measurements differently each time. By understanding these distinctions, project teams can develop tailored strategies to mitigate errors for more accurate data analysis.

Common Causes of Error

Common causes of error can range from human factors, such as misreading instruments, to environmental conditions that affect data integrity. For example, temperature fluctuations may influence sensitive measurements in scientific experiments. By systematically reviewing these potential causes, teams can implement measures such as standard operating procedures or regular training sessions to improve accuracy and reliability in project outcomes.

Approaches to Measure Error

There are several methods for measuring error, including statistical analysis and software tools. Statistical methods involve calculating error metrics like Mean Absolute Error (MAE) or Root Mean Square Error (RMSE) to quantify the degree of deviations from the expected values. Leveraging software tools can streamline these processes and provide more precise insights into performance by tracking error trends over time.

Proven Methods to Calculate Error

Diving deeper into proven methods for error calculation provides project teams with the tools necessary to ensure high-quality results. The following methodologies are favored in various industries for their effectiveness in quantifying error.

Method 1: Absolute Error Calculation

Absolute error is a straightforward way to evaluate discrepancies from the expected value. To compute absolute error, take the difference between the measured value and the true value. This can be crucial in scenarios such as laboratory measurements where precision is paramount. Detailed tracking of absolute error can lead to improved methodologies in future projects. For example, if you are measuring a chemical solution’s pH and observe an error of ±0.2, knowing this number helps adjust future measurements accordingly.

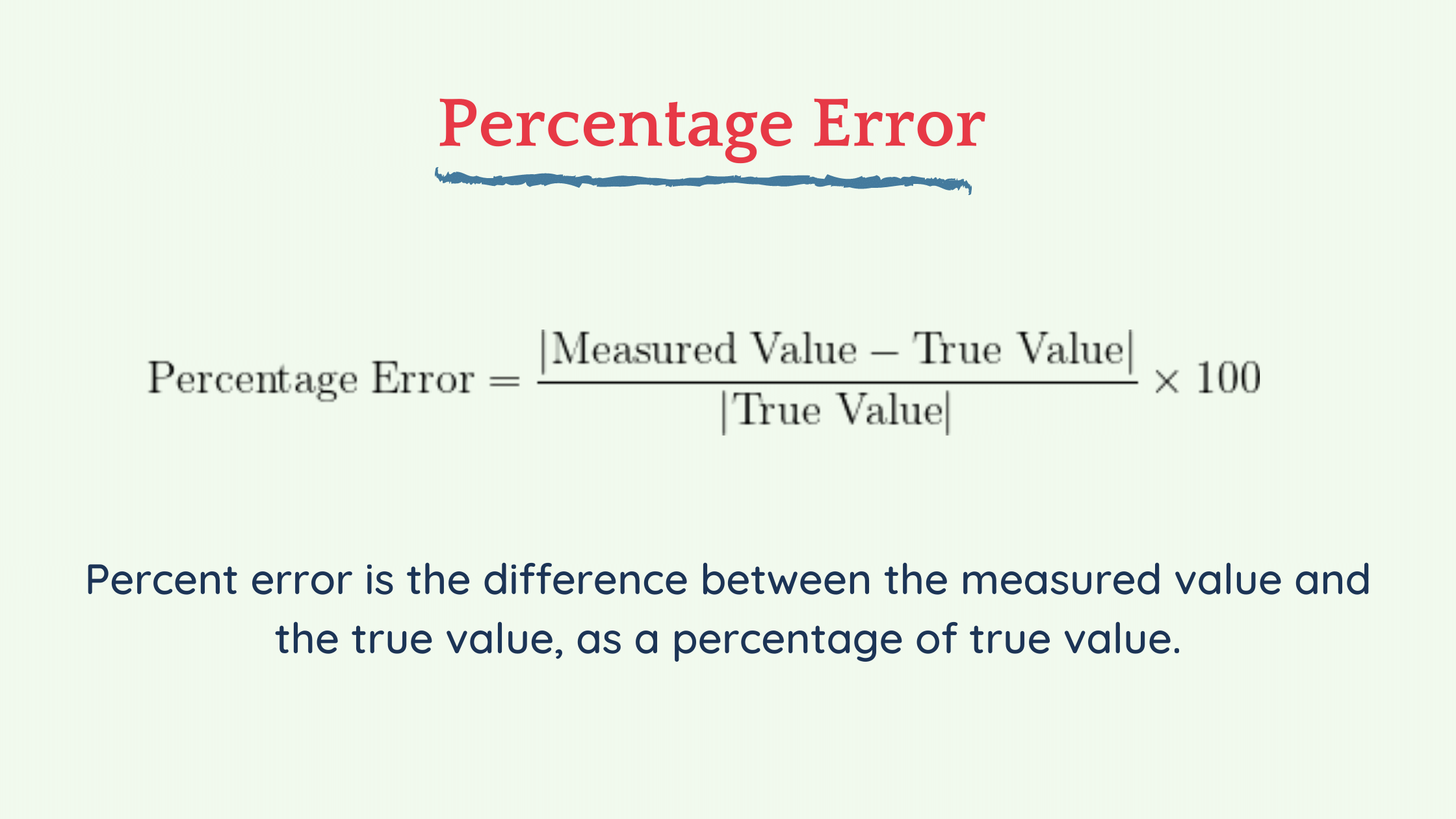

Method 2: Relative Error Calculation

Relative error offers a perspective on the error’s magnitude relative to the size of the measurement. This is often expressed as a percentage, giving teams a clearer idea of discrepancies in varying scales. For example, if the output of a manufacturing process is expected to yield 100 units but results in 98, the relative error is 2%. This approach aids in comparing different errors effectively, which is critical in large projects where proportions matter significantly.

Method 3: Comprehensive Error Analysis

Comprehensive error analysis encompasses all potential sources of error and combines multiple methods for a thorough evaluation. This could include methods like design of experiments (DoE) to systematically address variation factors and project variables. By comprehensively assessing error through designed experiments and detailed documentation, project leaders can significantly enhance quality control in manufacturing or scientific research environments.

The Importance of Error Calculation in Project Planning

Calculating error is integral to project planning as it informs future decisions and project directions. Effective error calculation not only identifies potential pitfalls but also guides resource allocation in corrective measures to optimize outcomes across various project phases. Strategic planning with accurate error metrics contributes to an overall enhancement of project performance.

Feedback Loops for Continuous Improvement

Integrating feedback loops based on calculated errors allows teams to not only correct issues post hoc but also to develop proactively. Implementing strategies where team feedback directly correlates with error metrics fosters a culture of continuous improvement. For instance, if a team consistently finds high error rates in a particular process, they can investigate and innovate solutions that enhance overall efficiency and quality.

Pilot Testing and Error Review

Pilot testing is an excellent way to validate assumptions and capture error metrics before full implementation. Conducting these tests allows for early detection of issues, enabling timely adjustments. Undergoing comprehensive error reviews after pilot runs can fundamentally refine processes, providing knowledge essential for full-scale project launches, thereby reducing risks of operational failures.

Incorporating Technology in Error Tracking

Modern projects benefit enormously from incorporating technology and data analytics tools designed for error tracking. Software can process vast datasets to identify patterns that may be challenging for human analysis. State-of-the-art data visualization tools can help teams foresee error trends, preemptively addressing issues and enhancing decision-making. Embracing technology contributes to sophisticated tracking of errors that will inform and improve best practices in the field.

Key Takeaways

- Understanding the types and causes of error is essential for effective measurement.

- Utilizing proven methods such as absolute and relative error calculations enables thorough planning.

- Incorporating feedback loops results in continuous improvement throughout the project lifecycle.

- Modern technology can enhance accuracy in error calculations, supporting project success.

FAQ

1. What are the main types of error in project measurements?

The two main types of errors in project measurements are systematic and random errors. Systematic errors consistently affect the results and can stem from equipment malfunction or biased measurements. Random errors result from unpredictable variations, making them harder to correct. Identifying these types is crucial for accurate error calculation.

2. How can I reduce systematic errors in my projects?

To reduce systematic errors, regular calibration of measurement devices is essential. Ensuring trained personnel operate equipment can also help minimize human errors. Implementing strict protocols and standard operating procedures are effective strategies to ensure all measurements are within acceptable limits, thus enhancing accuracy.

3. Why is relative error more useful than absolute error in certain cases?

Relative error is often more informative than absolute error because it provides a sense of scale relative to the true value. It allows for better comparisons between different datasets or measurements that vary in size. By expressing errors as a percentage, it’s easier to understand the impact of errors across various projects.

4. Can technology really improve error tracking?

Yes, incorporating technology like data analytics and visualization tools can vastly enhance error tracking. These tools can analyze large datasets to identify trends and patterns in errors that might not be apparent through manual analysis. This results in more accurate tracking, leading to better decision-making in project management.

5. How can pilot testing prevent costly errors?

Pilot testing allows teams to validate assumptions and identify potential errors before full-scale implementation. By doing so, corrective actions can be taken during the pilot stage, thus averting larger, costlier errors down the line. Comprehensive error reviews during this phase can fundamentally refine processes before scaling up.

“`